Pre-treatment of the product

Necessary pre-treatment of the product, such as pasteurisation, or the addition of additives can be carried out before the spray drying process.

A dosing device is available for the adding of flow additives such as silicon dioxide during the spray drying process.

Food conservation by drying

Humans have, over the course of the centuries, developed a number of methods to keep foodstuffs edible and to be able to store them. One of these methods is conservation by dehydration, so-called drying. The industrial drying of foodstuffs began at the end of the 19th century and is still used nowadays in a number of different areas. In this way, the foodstuffs are not just dried as a whole, its associated aromas and extracts are also dried.

There are a number of methods for the drying of foodstuffs, which have different effects on the contents and quality of the product. It is not only temperature that plays a large role thereby, but also the length of time that the foodstuff is exposed to the heat. One of these processes which is in use from the laboratory scale right up to large-scale commercial production, is spray drying.

The principle of spray drying

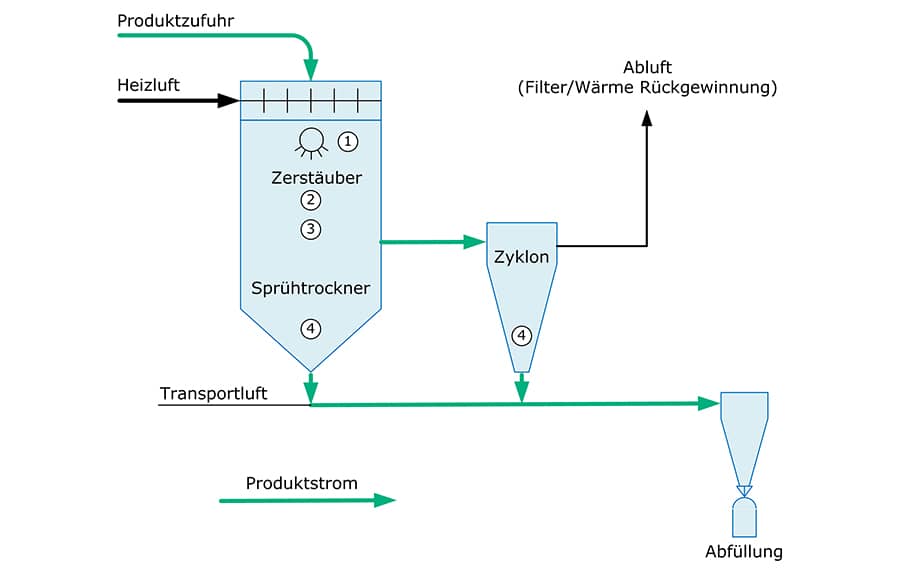

Spray drying effectively uses the principle of surface area enlargement. The spray dryer belongs to the class of convective dryers, in which the energy for the evaporation of the solvent (which is often water) is transferred from the drying gas to the material that is to be dried by thermal conduction. Spray drying is a sequence of four processes and takes place in a matter of seconds.

Step 1: Atomisation

Liquid products are atomised into fine droplets at the upper end of the dryer with the help of an aggregate. Here, there are two fundamentally different types of atomisation:

a) Rotation or centrifugal force atomisation

b) Nozzle atomisation

In rotation or centrifugal force atomisation, the material to be dried is finely atomised using a rotating disc travelling in the direction of the hot air stream. Due to the approximately horizontal direction of the atomised droplets, rotating spray dryers require a tower with a relatively large diameter.

In nozzle atomisation, the raw material is sprayed into the hot air stream using a nozzle, either in the direction of the hot air stream (same current) or in the opposite direction (opposite current)

Step 2: Contact/mixing of the spray solution with the drying medium (hot air)

The finely sprayed fluid particles come into contact with the hot air. As soon as the droplets have formed, they must be mixed with a sufficient amount of warm drying gas. Mixing of the atomizers occurs as a result of the high speed of the droplets upon entry into the dryer.

Step 3: Drying

95% of the water in the droplets evaporates within seconds. The round droplets that arise from the atomisation are dried very quickly as a result of their large surface areas and hence their large areas of contact with the hot gas stream. Even with the air supplied at a very high temperature, the evaporation cooling keeps the temperature of the good low and that guarantees gentle drying.

Ideally, the spraying property leaves the dryer at exactly the moment in which all of the water has evaporated. Hereby, the resulting particles differ in terms of shape, size, particle size distribution and stability according to the process parameters that were set and the source material that was used.

Step 4: Separation

The main quantity of the particles in the spray dryer fall downwards as a result of gravity and are led away into the transportation air duct. The main amount of air will be lead into the downstream Cyclone. Because of this, the flow velocity will decelerate and eventually, particles that were carried along will be separated and led into the transportation air duct. Afterwards, the product will be filled into the containers.

![[Translate to english:] Sprühtrocknung Lebensmittel [Translate to english:] Sprühtrocknung Lebensmittel](/fileadmin/Content/07_Lohnherstellung/Lohnherstellung_Spruehtrocknung%20Lebensmittel/lohnherstellung-sprueh-lebensmittel-header.jpg)