When will testing be done?

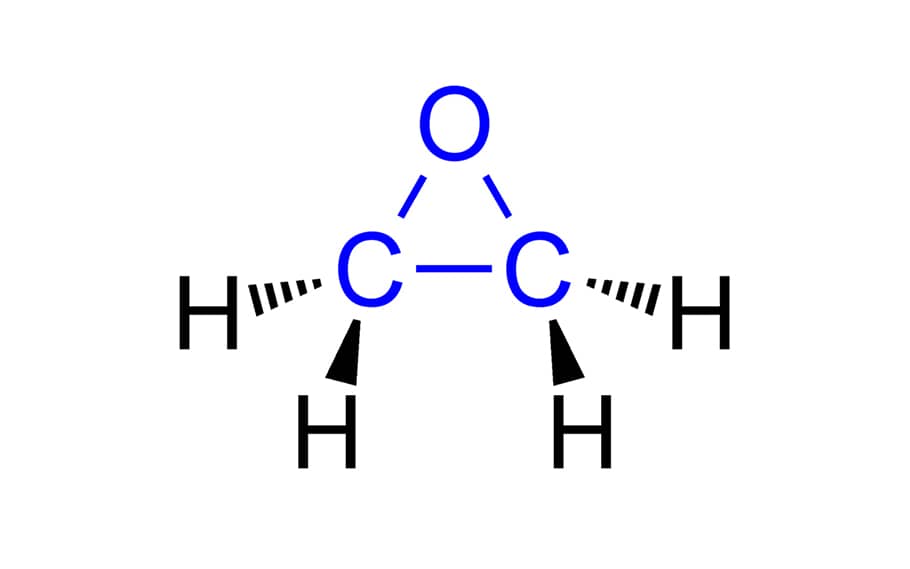

Sterilisation will be carried out in a separate work phase in special facilities after the production of a medical device. After exposure to ethylene oxide comes the aeration phase. Afterwards, the samples will be analysed either in-house or will be sent by courier to a specialised service laboratory for analysis.

What should be observed during transportation?

Transportation is also regulated in ISO 10933-7 and is generally performed in dry ice. Losses due to evaporation will be minimised as a result. Cooling using freezing packs is not permissible. It is particularly important that untreated control samples are sent protected and separately. Only in this way can contamination from the treated samples be avoided.

The advantages of external testing by a contract laboratory

There are many years of technical expertise available in a service laboratory. The high sample throughput allows testing of the samples to usually be cost-effective. In the event of questions or problems, then there are experienced and competent technical experts available to act as contact people for the customer.

How will analysis be performed?

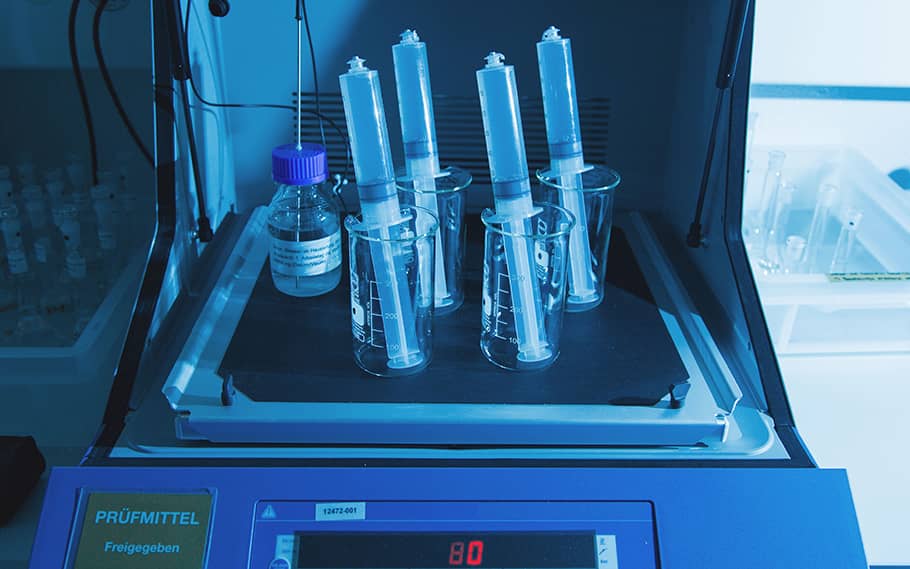

The analysis will be implemented by performing an extraction and following it with content determination using GC-FID. Depending on the intended use of the medical device, different methods will be used.

Extraction by simulated application

Products with a short term patient contact (<24 hours) fall into this category, category A. Here, contact of the product with the patient is simulated. For this simulation, the surfaces will be rinsed with water and the sterilisation in the rinse water will be determined.

Exhaustive extraction

Products with a longer period of patient contact (<30 days) fall into this category. The process has the goal of investigating the complete residual content of a medical device. Extraction will be performed until less than 10% of the content ascertained in the first extraction is obtained or until the analytical data indicate that there will be no more significant increase in the cumulated residual content. This process is used for example, for implants that remain for a long period of time in the body.

As the amount of work required can vary greatly depending on the number of extraction rounds, the costs are very different according to the type of product and cannot be calculated exactly in advance.

![[Translate to english:] Ethylenoxidbestimmung: HPLC-Vials [Translate to english:] Ethylenoxidbestimmung: HPLC-Vials](/fileadmin/Content/04_Medizinprodukte/Medizinprodukte_Ethylenoxidrueckstaende/medizinprodukte-ethylenoxidrueckstaende-header.jpg)