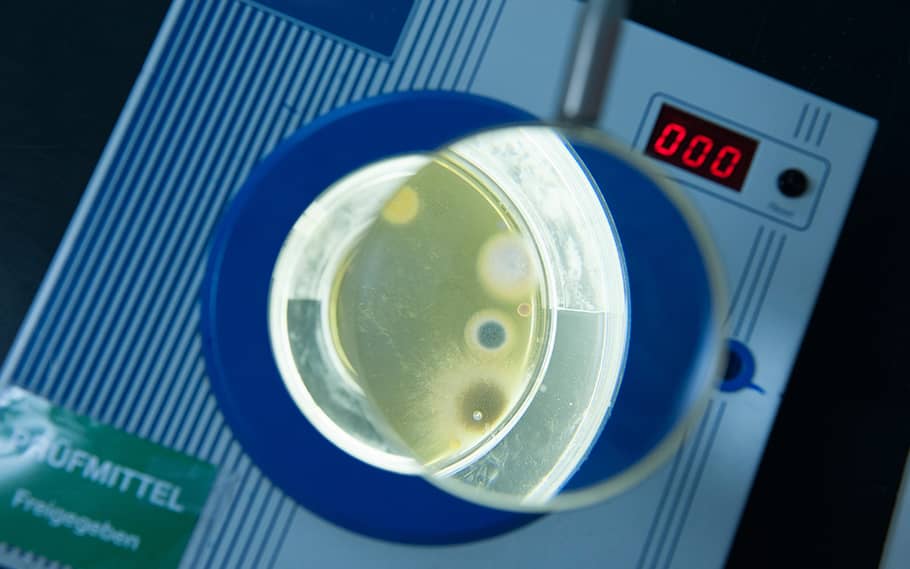

Micro-organisms such as bacteria, fungi and viruses are ubiquitous in the environment. In part, their presence is necessary for the processing of products (fermentation and ripening) and in part, their presence as pathogens and the causes of rot and decay is unwanted.

Sufficient knowledge of the microbiological status of the foodstuff is necessary to be able to evaluate its quality. In Switzerland, this assessment is based on the Federal Law on Foodstuffs and Consumer Products, the Food Hygiene Ordinance of the Swiss Federal Department of Home Affairs (HyV). If there are no statutory regulations, the evaluation can be carried out in accordance with the recommendations of recognised expert groups (The German Society for Hygiene and Microbiology, DGHM).

Are you looking for an accredited Swiss contract laboratory for the microbiological control of your products? We test for you in accordance with recognised standards and the Food Hygiene Ordinance.

Our customers come from a variety of different sectors: restaurants, producing companies, butchers, supermarkets, beverage producers or foodstuff companies. We distinguish ourselves by our proximity to the market and to our customers.

The following is true for all of our customers: we will process your samples quickly, competently and reliably.

Do you have any questions about the interpretation of the legal regulations or do you need support with evaluating the test results?

![[Translate to english:] Lebensmittelanalytik: Mikrobiologische Prüfungen [Translate to english:] Lebensmittelanalytik: Mikrobiologische Prüfungen](/fileadmin/Content/05_Lebensmittel/Lebensmittel_Mikrobiologie/lebensmittel-mikrobiologie-header.jpg)