Share article

Share this article on your favorite social media channel.

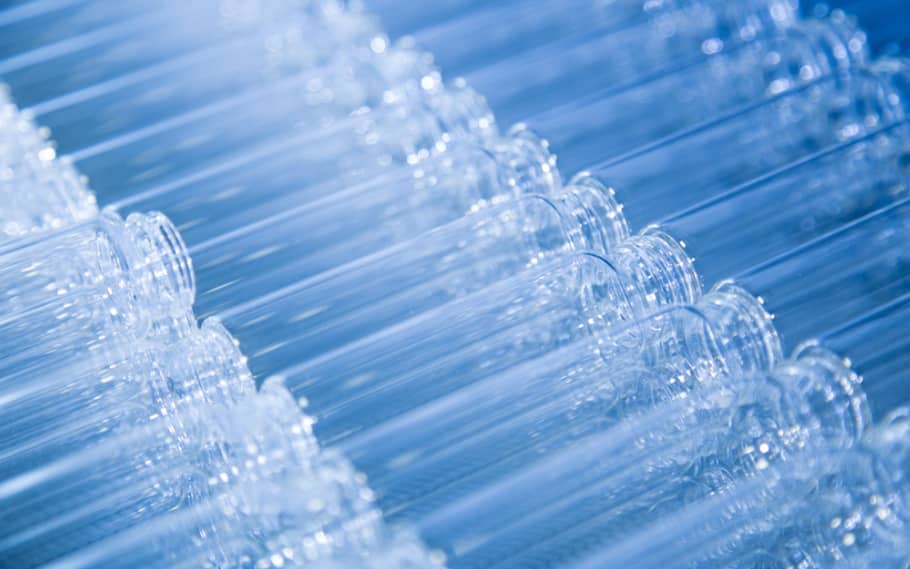

As water in various forms is the main raw material for pharmaceutical production, quality problems with treated water are one of the most frequent causes of recalls. In order to ensure water quality meets the requirements, special attention must be paid not only to the facilities that produce pharmaceutical water, but also to the pipelines that distribute the water.

Newly built water systems must be put through their paces before routine operation can start up. The sampling points are defined on the basis of a risk analysis. In the course of various plant qualification phases, analysis samples are taken at these points and tested for a range of quality-related parameters, such as conductivity, microbiological impurities, TOC value, nitrates and heavy metals. Final performance qualification (PQ) may very well require testing several hundred samples per day over a period of a few months.

As a GMP-accredited and FDA-registered Swiss contract laboratory, UFAG Laboratorien AG can provide you support with this task. We have many years of experience in the field of pharmaceutical water analysis at all quality levels in accordance with current pharmacopoeial methods. Our own transport service for sample logistics also helps us ensure the timely performance of microbiological analyses.